What is Spunbond

The most recent

Everything Need to ...

1402/10/26Spunbond fabric is one of the non-woven fabrics made from polypropylene fibers. Due to its positive features and advantages

Hydrophilic Fabric R...

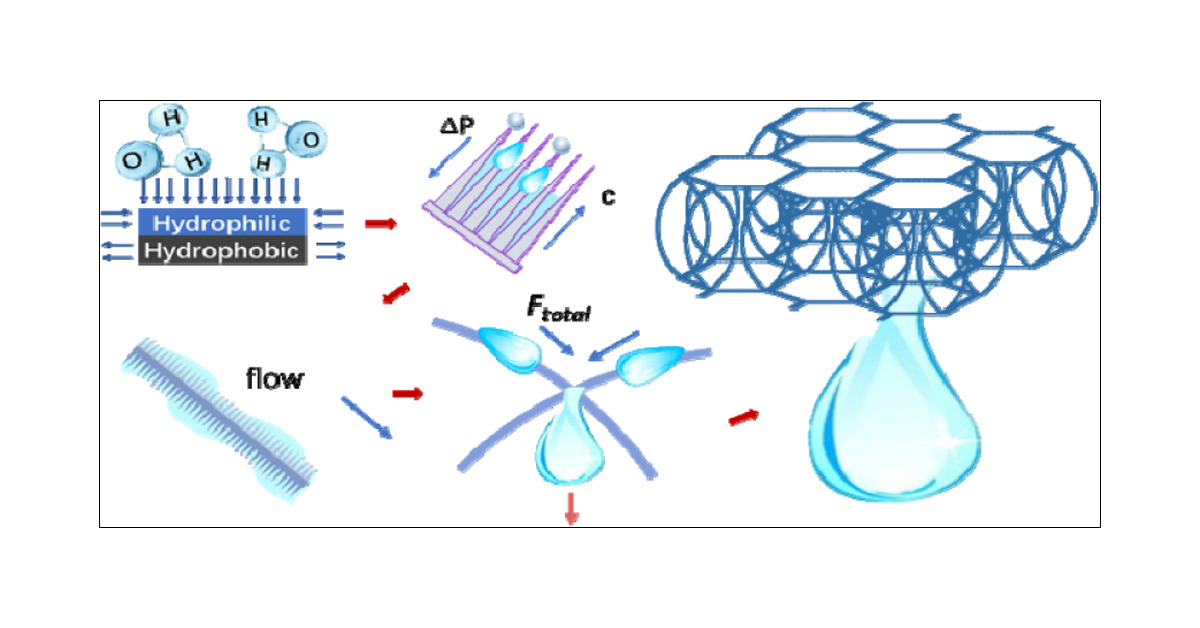

1402/09/14In the quest to combat water scarcity, innovative solutions like fog harvesting have emerged as promising alternatives

Hydrophilic Fabric

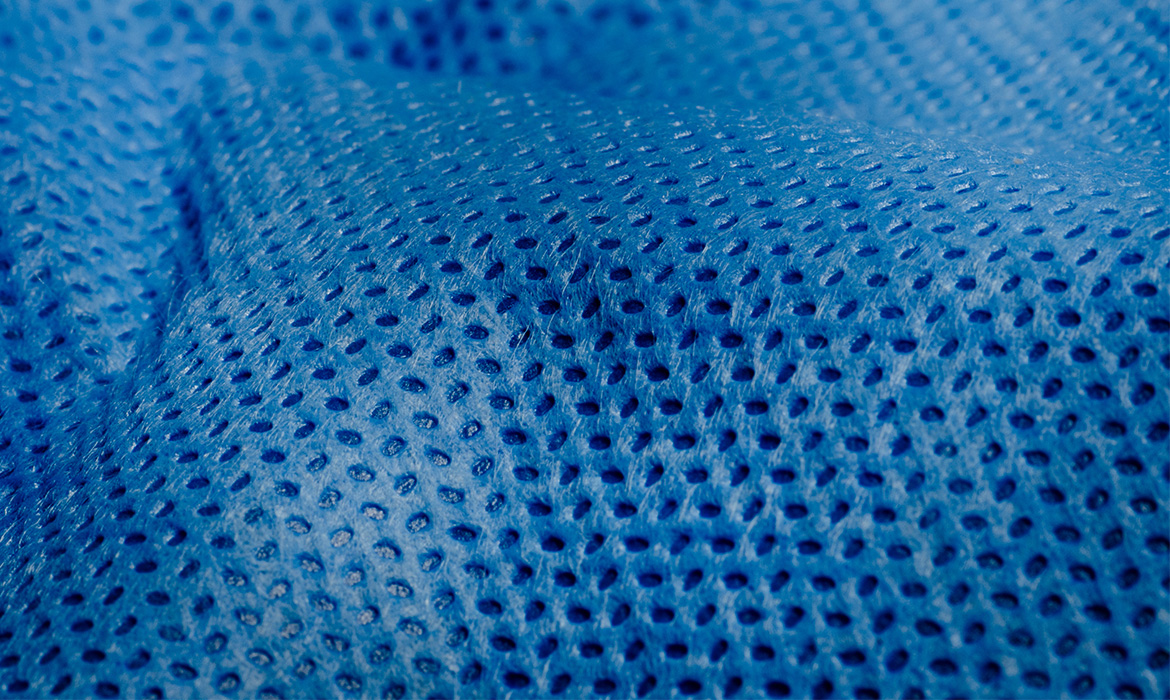

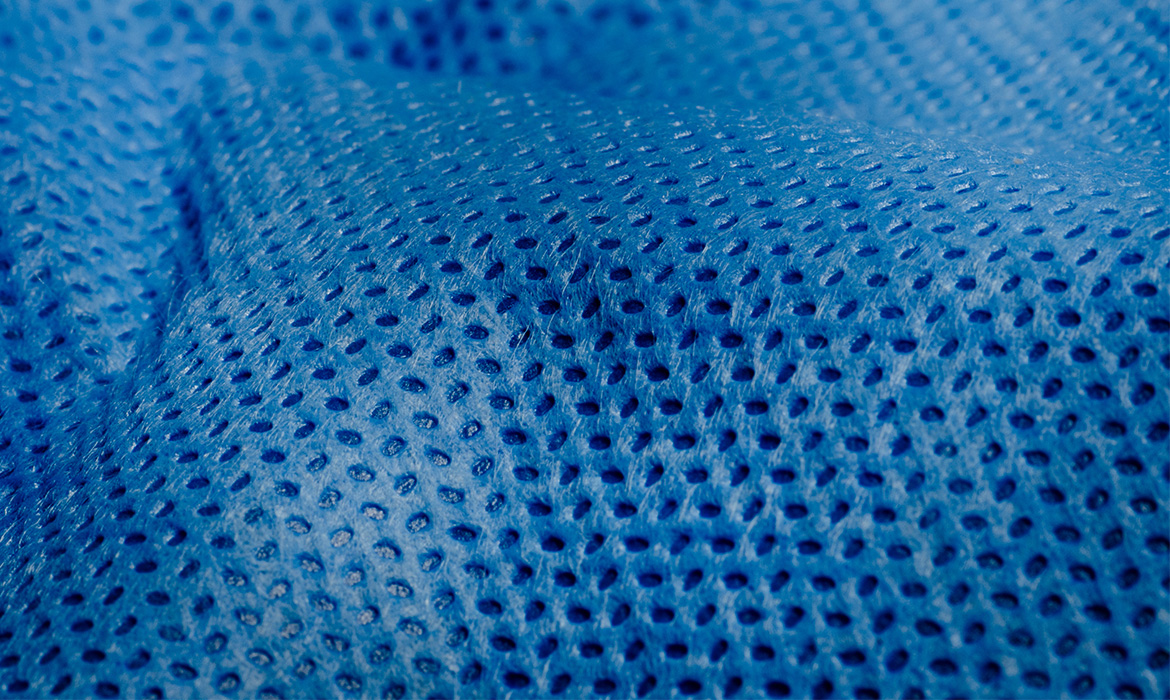

1402/07/12 Given the importance of hygiene and adherence to safety principles in places like hospitals, manufacturers have aimed to produce products that are particularly valuable and effective in this area. Hydrophilic fabric is one of those products designed for this purpose

The most visited

Where to Buy Spunbon...

1402/07/08Spunbond fabrics belong to a category of non-woven textiles made from polypropylene. Unlike conventional fabrics constructed with warp and weft, spunbond materials

What is Spunbond

1402/07/10One of the most captivating, functional, and widely-used fabrics in the domestic market is the spunbond fabric. This fabric plays a significant role in the production of industrial products due to its unique characteristics.

Hydrophilic Fabric

1402/07/12 Given the importance of hygiene and adherence to safety principles in places like hospitals, manufacturers have aimed to produce products that are particularly valuable and effective in this area. Hydrophilic fabric is one of those products designed for this purpose

subscribe to newsletter

What is Spunbond

1402/07/10

One of the most captivating, functional, and widely-used fabrics in the domestic market is the spunbond fabric. This fabric plays a significant role in the production of industrial products due to its unique characteristics. Many industries would face challenges in product manufacturing and distribution without it. In this article, we will discuss spunbond and the reasons for its importance in depth.

If you are in an industry that deals with fabrics, you must be thoroughly familiar with spunbond. If you are planning to start a business related to textiles and fabrics, you will need to acquaint yourself with spunbond. In this section, we will provide comprehensive details about spunbond fabric. One primary identifier for spunbond is that they are non-woven fabrics. Although spunbond is among the most consumed fabrics and many surrounding products are made with it, some believe it's a new production of domestic factories. However, it's important to note that this product has a long history. Industry professionals recognize spunbond by other names such as:

• Needle non-woven, etc.

From these definitions, you should understand that, unlike many available fabrics in the market, this product is not made from yarn fibers. In fact, spunbond is made using a special pressing machine. To better understand the fibers and overall structure of spunbond, consider the structure of carpets. Spunbond fibers are somewhat similar to carpet fibers. The applications of spunbond are so extensive that you'll be amazed when you get to know them. In subsequent sections, we will explore the uses of these non-woven textiles.

How Spunbond is Produced

To produce spunbond fabric, a specialized machine called an extruder is required. Initially, raw materials for fabric production are introduced into this machine. Polypropylene is the primary component of spunbond. This material is heated at high temperatures until fully melted. Following this, to cool the molten materials, they are passed through a needle-like surface. After cooling, the materials are smoothed and evened out using a roller-like tool called a calender. The back-and-forth movement of the calender on the materials ensures the desired thickness of the spunbond is achieved. Thickness is a critical factor in spunbond, and it can dictate its applications. Therefore, a great deal of precision and expertise is required during the calendering process.

Characteristics of Spunbond

• Spunbond fabrics exhibit high resistance against ultraviolet rays, ensuring they don't get damaged.

Factors Influencing the Diversity of Spunbond

Spunbond fabrics can be categorized into various groups based on differences in their structure and appearance. Some of the factors contributing to the diversity of spunbond include:

• The degree of softness.

Given these factors, it's evident that the world of spunbond is vast and varied, and individuals can choose from a plethora of spunbond fabrics based on their specific needs.

Applications of Spunbond Fabric

Medical Industry

One of the most crucial applications of spunbond is in the medical sector. It's used for producing various disposable hospital garments, surgical gowns, surgical caps, shoe covers, multi-layer masks, etc., which many of us might not have been previously aware of.

Packaging Industry

Spunbond is extensively used for producing covers for furniture, household appliances, cars, clothing, and for packaging food products like legumes, fruits, rice, etc. In terms of packaging and covering products and parts, spunbond offers superior quality.

Automotive Industry

Many of the interior decorations of cars, painting processes, and soundproofing are done using spunbond.

Construction and Road-making Industries

For interior decoration, building moldings, producing building covers, constructing false walls, etc., spunbond is employed.

Agriculture Industry

Start a conversation

Hello ! Click on a member below and chat.