Introduction to Nonwoven Fabric and Its Applications

The most recent

What is Geotextile?

9/20/2025Geotextile is a type of engineered fabric used in civil engineering projects. At HarirBaft Amir, we provide geotextiles at the best prices.

What is Agricultural...

9/12/2025Agricultural fabric is made from materials such as polypropylene or polyethylene and is manufactured using technologies like weaving or spunbond processes.

What is Nano Fabric?

8/20/2025Nano fabric, or nanofabric, is one of the key achievements of nanotechnology in the textile industry, revolutionizing our understanding of fabrics and their applications.

The most visited

Where to Buy Spunbon...

9/30/2023Spunbond fabrics belong to a category of non-woven textiles made from polypropylene. Unlike conventional fabrics constructed with warp and weft, spunbond materials

What is Spunbond

10/2/2023One of the most captivating, functional, and widely-used fabrics in the domestic market is the spunbond fabric. This fabric plays a significant role in the production of industrial products due to its unique characteristics.

Crafting Melt Blown ...

9/30/2023Melt blown textiles have emerged as one of the most sought-after materials, gaining prominence especially in the healthcare field

subscribe to newsletter

Introduction to Nonwoven Fabric and Its Applications

7/17/2025

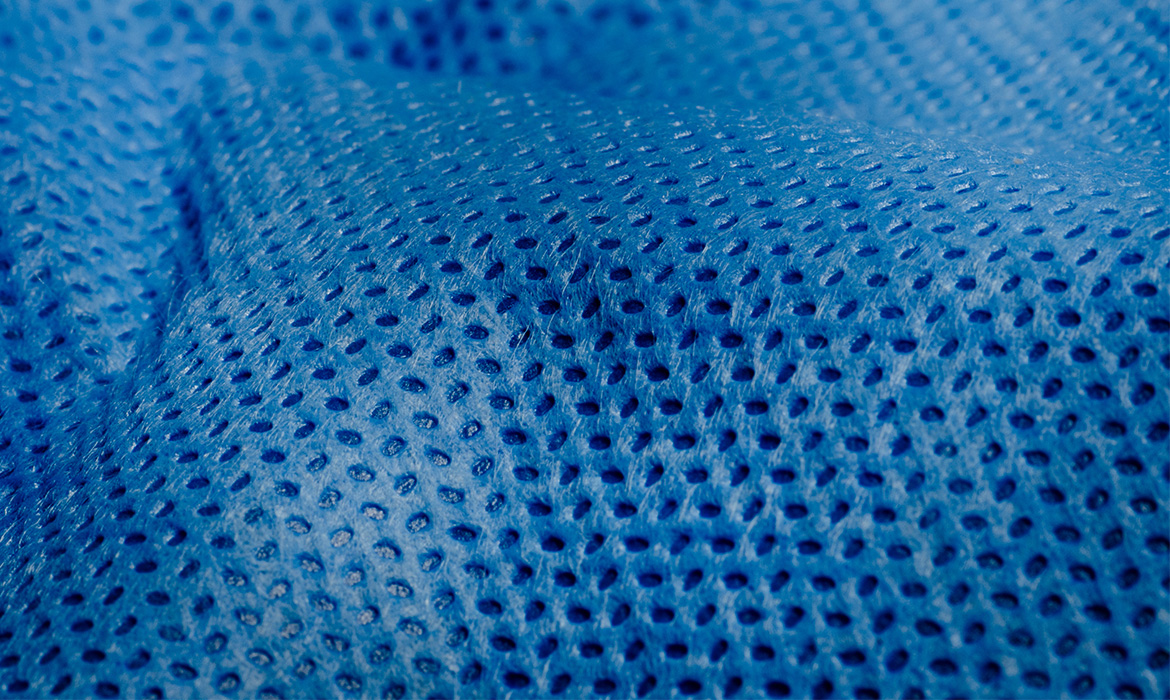

In the diverse and dynamic world of the textile industry, sometimes a small change in the structure or type of fabric can lead to a major transformation in performance and application. Some of these innovations are so impactful that their influence can be traced across various fields, from medicine to fashion. One such innovation that has gained significant attention in recent years is a unique fabric known as nonwoven or needle-punched fabric. With its distinctive features, it offers both delicacy and high functionality. If you are looking to discover one of the most practical yet lesser-known types of textiles, join us as we explore the world of this special fabric.

Introduction to Nonwoven Fabric

Nonwoven fabric, also called needle-punched fabric, is a special type of textile produced using mechanical processes without the involvement of traditional yarn, warp, or weft. In this fabric, fibers are entangled with each other using special needles instead of being woven, creating a uniform, durable, and functional layer. This method, commonly known as Needle Punch, allows the production of fabrics with different weights, densities, and specific mechanical properties.

Needle-punched fabrics fall under the category of spunbond nonwovens and can exhibit a wide range of characteristics depending on whether natural or synthetic fibers are used. Their applications extend beyond the textile industry into fields such as filtration, automotive, medical, and even interior design. Notably, the production process is faster and more cost-effective compared to traditional weaving methods, making these fabrics an attractive option for many industries.

Unique Features of Nonwoven Fabrics

Due to their special structure, nonwoven fabrics have unique characteristics that distinguish them from other types of textiles. These properties have given them a significant role in many industrial, healthcare, and technical fields. Key features include:

- High absorbency: Their porous structure increases the ability to absorb moisture, liquids, or even dust particles more effectively than traditional woven fabrics.

- Excellent air permeability: The loose arrangement of fibers allows better airflow, making them ideal for use in masks, filters, and hygienic clothing.

- Remarkable mechanical strength: Despite their thin or delicate appearance, nonwoven fabrics show good resistance to tearing and pressure, especially when made from high-quality synthetic fibers.

- Recyclability and eco-friendliness: Many nonwoven fabrics are made from recyclable fibers, which is particularly important in industries focused on environmental concerns.

- High flexibility in production: They can be produced in various thicknesses, colors, and properties, making them suitable for a wide range of applications.

- Chemical and heat resistance (in some types): When made with specialized fibers such as polypropylene or polyester, they can perform well even under harsh industrial conditions.

Applications of Nonwoven Fabrics in Different Industries

As mentioned earlier, nonwoven fabrics are widely used across industries due to their unique structure. They are not only utilized in consumer products but also play a key role in specialized and industrial applications. Major areas of use include:

- Medical and healthcare: Used in respiratory masks, surgical gowns, caps, disposable shoe covers, dressings, and disinfectant covers.

- Automotive industry: Applied as sound insulation, interior roof lining, filters, and interlayers to reduce friction and vibration.

- Agriculture and greenhouses: Used for protective plant covers, soil filters, and erosion control.

- Filtration industry: Essential in industrial and household filters for capturing air and liquid pollutants.

- Interior design and architecture: Found in carpets, acoustic insulation, and even industrial curtains.

The wide variety of applications highlights the versatility of this fabric in meeting diverse industrial needs.

Advantages and Disadvantages of Nonwoven Fabrics

Although nonwoven fabrics are practical and popular, like any material, they have both advantages and limitations. The main advantages include:

- Fast and cost-effective production

- High breathability and airflow

- Recyclability and eco-friendly manufacturing

- Lightweight with sufficient strength

- Variety in thickness and density

The key disadvantages are:

- Lower resistance to repeated washing in some types

- Sensitivity to high temperatures (especially synthetic fibers)

- Limited long-term durability compared to woven fabrics

Therefore, choosing the right nonwoven fabric depends on the intended use. When selected properly, it can provide excellent performance.

Differences Between Nonwoven and Other Fabrics

Unlike traditional fabrics that are formed by the regular weaving of warp and weft, nonwoven fabrics are created by physically entangling fibers without spinning or weaving. This difference in production leads to distinctive properties. The main differences include:

- The nonwoven structure reduces production time and costs.

- Greater flexibility in design regarding thickness, shape, and color compared to woven fabrics.

- Specialized applications in filters and industrial equipment, where woven fabrics are less common.

These differences make nonwoven fabrics a modern choice for today’s needs, particularly where efficiency and production speed are critical.

Tips for Buying and Maintaining Nonwoven Fabrics

To fully benefit from the advantages of nonwoven fabrics, attention to certain points during purchase and maintenance is essential. The most important recommendations are:

- Identify the intended application: Define whether the use is medical, industrial, or household to choose the right type.

- Check fiber quality: Selecting products made from high-quality fibers ensures better performance and longer lifespan.

- Storage conditions: Keep nonwoven fabrics in a dry, cool place and avoid washing them with strong detergents.

One of the most crucial factors in purchasing is choosing a reputable supplier. Companies with experience, product variety, and quality assurance are more reliable. Harir Baft Amir is one of the leading manufacturers of spunbond fabric and meltblown fabric in Iran, offering high-quality nonwoven fabrics in various grades. Customers can confidently purchase their desired products by visiting the company’s website.

Start a conversation

Hello ! Click on a member below and chat.